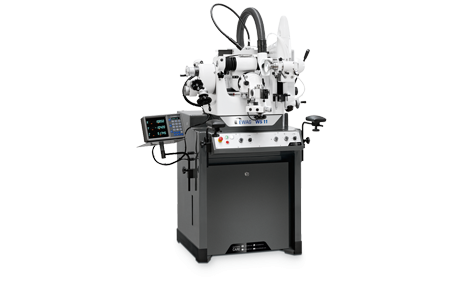

WS 11

The Universal grinders WS 11 and WS 11-SP are especially for manufacturing and regrinding of high precision small tools and production parts from hard metal, steel or other materials.

With the universal grinding it WS11wird made possible from carbide, HSS or other materials to produce micro tools and production parts and regrind.

Thanks to the hydrostatic grinding spindle is constant defines the thermal expansion, therefore, tolerances of 0.0002 mm possible. At the same time, with the measurement optical Zerspannungsprozess 1: 1 monitored and controlled during the engagement of the grinding wheel.

Benefits leave nothing to be desired:

- By WS 11 concept is cylindrical and conical tools can grind and measure in a single setup.

- Single pieces as well as smaller series are equally honed economic.

- Extensive range of accessories allow quick adjustment of the machine to the respective machining task.

Highest accuracy in conjunction with performance and reliability contribute to increase the quality of the tools essential in many industries.

Specifications

| Grinding spindle drive, three-phase motor kW (min-1): | 0.3 |

| Speed range 1 / min: | 2500/3500/4800/6800 |

| X-axis, cross travel mm: | 100 |

| X-axis, reading accuracy mm: | 0.01 |

| Adjustable speed min-1: | 100-1300 |

| 102 mm / 25 kg: | 100 |

| Y-axis grinding stroke vertical, straight mm: | |

| 150 mm / 100 kg: | 0.01 |

| Y-axis reading accuracy mm: | |

| Z-axis feed stroke horizontal mm: | 100 |

| Z-axis reading accuracy mm: | 0.001 |

| Workpiece spindle drive kW: | 0.25 |