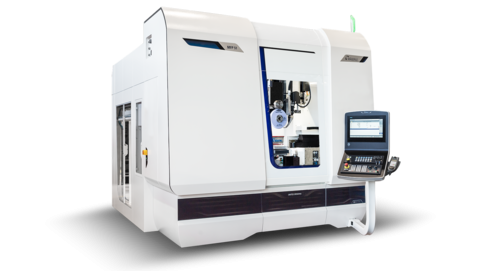

MFP 51

In its basic version this sturdy grinding center comes with an integrated tool changer in a gantry design with 66 positions. The magazine can be flexibly loaded with various grinding wheels, diamond rolls, measuring probes and tools for drilling and milling operations. The large capacity of the tool changer enables efficient machining of several different workpieces without altering the tooling.

Portal Tool Magazine

An identification system for grinding wheels and tools is optionally available. The tool is inserted into a holder in the loading station. The data stored on an RFID chip is securely imported prior to the loading process. The chip is written with the current data when the grinding wheel is unloaded. The tool identification eliminates the probability of errors when entering the tool data in the machine, guaranteeing safe and uninterrupted operation.

Specifications

| Linear Axes | |

|---|---|

| Max. Travel X | 500 mm |

| Max. Travel Speed X | 50,000 mm/min |

| Max. Travel Y | 650 mm |

| Max. Travel Speed Y | 30,000 mm/min |

| Max. Travel Z | 650 mm |

| Max. Travel Speed Z | 30,000 mm/min |

| Spindle Drive | |

| Max. Spindle Power | 50 kW |

| Max. Number of Revolutions | 12,000/ min |

| Max. Grinding Wheel Diameter | 300 mm |

| Max. Grinding Wheel Width | 60 mm |

| Swiveling Axes | |

| Swiveling Range A | 210° |

| Swiveling Range B | 360° |

| Swiveling Range C | 360° |

| Workpiece Data | |

| Table Size | 500 x 650 mm |