Products

- High Speed Machine -- Mikron HSM --- Mikron MILL S 400 --- Mikron MILL S 500 --- Mikron MILL S 600 --- Mikron MILL S 800 --- Mikron MILL S 200 U --- Mikron MILL S 400 U --- Mikron MILL S 600 U --- Mikron HSM 500 --- Mikron HSM 700 --- Mikron MILL S 400 Graphite --- Mikron MILL S 500 Graphite -- Mikron XSM --- MILL X 400 --- MILL X 600 --- MILL X 800 -- MILL X U Series --- MILL X 400 U --- MILL X 600 U - High Performance Machine -- MIKRON HPM --- Mikron MILL P 500 U --- Mikron MILL P 800 U --- Mikron HPM 1150U --- Mikron HPM 1350U --- Mikron HPM 1850U --- Mikron Mill P 900 --- MSP: Machine and Spindle Protection - High Efficiency Machine -- MIKROM HEM --- Mikron MILL E 500 U --- Mikron MILL E 700 U

- Die Sinking EDM -- AgieCharmilles FORM E series --- FORM E 350 --- FORM E 600 -- AgieCharmilles FORM P series --- FORM P 350 --- FORM P 600 --- FORM P 900 -- AgieCharmilles FORM S series --- FORM S 350 -- AgieCharmilles FORM X series --- FORM X 400 --- FORM X 600 - Wire Cut EDM -- MICRO MACHINING --- AgieCharmilles CUT 1000 --- AgieCharmilles CUT 1000 OilTech -- AgieCharmilles CUT 2000 / 3000 Series --- AgieCharmilles CUT 2000 S --- AgieCharmilles CUT 3000 S --- Agie Charmilles CUT 2000 X --- AgieCharmilles CUT 2000 OilTech -- HIGH SPEED MACHINING --- AgieCharmilles AC Progress VP2 --- AgieCharmilles AC Progress VP3 --- AgieCharmilles AC Progress VP4 --- CUT 200 dedicated wire EDM for areospace and aeronautics, die/mold and medical applications -- CUT P Series --- CUT P 350 --- CUT P 550 --- CUT P 800 --- CUT P 1250 -- TOP END ACCURACY --- AgieCharmilles CUT 1000 -- GENERAL PURPOSE --- CUT E 350 --- CUT E 600 - Hole Drilling EDM --- DRILL 20

- Laser Texturing -- Laser S Series --- LASER S 1000 U --- LASER S 1200 U -- Laser P Series --- LASER P 600 U --- LASER P 1000 U --- LASER P 1200 U --- LASER P 1200 U DEDICATED --- LASER P 4000 U - Laser Micromachining --- ML-5 --- MLTC - Additive Manufacturing --- DMP Factory 350 --- DMP Factory 500 --- DMP Flex 350 --- CUT AM 500

--- Certified Wires --- Graphite Electrodes --- Filters --- Resins and Deionisation --- Drilling Electrodes --- Metallic Electrodes --- Dielectric

- Tooling --- Electrode Manufacturing & EDMing --- Wire EDMing --- Parts Production --- Powder Compacting Technology --- Additive Manufacturing - Automation --- System 3R WorkPal 1 --- System 3R WorkPartner 1+ --- System 3R Transformer WorkMaster --- System 3R Transformer 6-Axis Robot

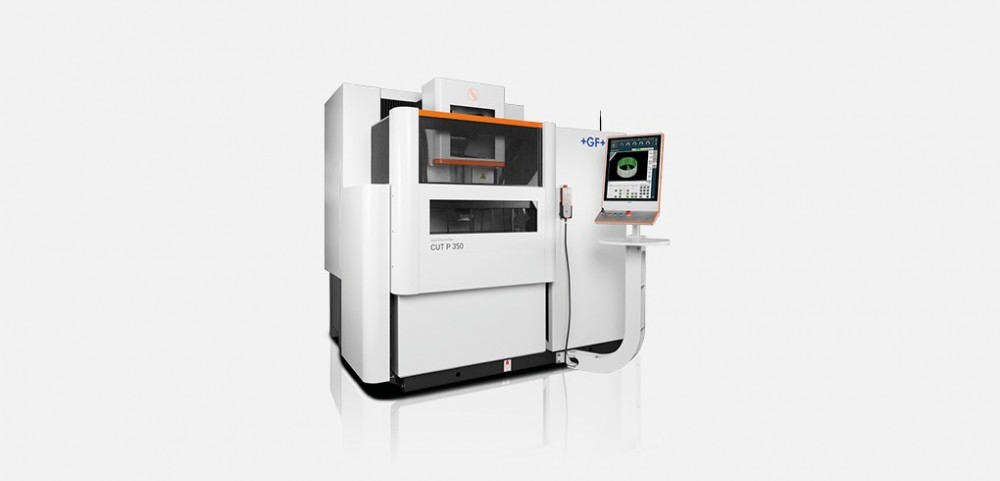

CUT P 350

Repeatability and longer tooling life are “must haves” with component miniaturization and increasing production volumes. Achieve the accuracy, machining repeatability and finer surface finishes essential to your daily success with the new CUT P wire-cutting EDM series. Shorter time to market, larger product portfolios and zero-defect manufacturing call for shorter, more efficient manufacturing flows, more flexible production lines, and more reliable processes. Overcome these challenges with the CUT P series’ machining quality and efficiency solutions to optimize your production tool.

Increase Your Design Possibilities

The time you spend cutting is the time you are making money. That’s why GF Machining Solutions optimizes your productivity and machine availability with SMART and connected solutions

Specifications

Main Specifications

Type of machining

Submerged wire-cutting

Dimensions of complete equipment

2050 x 2234 x 2154 mm

Machining Area

Vertical sliding door

Automatic

Max. Workpiece dimensions (top load)

1000 x 150 x 220 mm

Max. workpiece dimensions (front load)

800 x 550 x 220 mm

Max. Workpiece weight

750 kg

Dimensions of table

680 x 450 mm

Floor-to-table distance

1000 mm

Total volume of dielectric

700 l

Main Specifications

Total weight of equipment without dielectric

2450 kg

Travel

X, Y, X travel

350 x 220 x 220 mm

U, V travel

350 x 220 mm

Axes

Max. speed (X, Y and U, V axes)

3 m / min

Integrated collision protection (ICP)

Standard on 5 axes

Hover over image to enlarge

Hover over image to enlarge