MGC RH

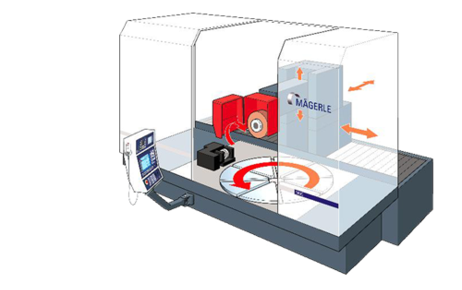

With table diameters of up to 2.5 metres and a maximum load bearing capacity of 12 tons, the MGC rotary table grinding centre is unequalled throughout the world. Well-known companies in the power turbine industry rely on this powerful concept. This grinding centre is unrivalled particularly when it comes to machining turbine blades with Hirth gears and Curvic couplings of the highest quality.

First-Class Results For Hirth Gears & Curvic Couplings

The direct-drive rotary table mounted on hydrostatic bearings ensures the necessary precision, with a positioning accuracy of less than three angular seconds.

Specifications

| X-Axis | ||

|---|---|---|

| longitudinal stroke | mm | 1400 ... 2600 |

| Travel speed | mm/min | 0...20000 |

| Y-Axis | ||

| vertical stroke | mm | 450/650/900/1200 |

| Travel speed | mm/min | 0...10000* |

| Z-Axis | ||

| transverse stroke | mm | 500 ... 750 |

| Travel speed | mm/min | 0...10000* |

| V-axis profile crushing device, roll width, max. | mm/min | 167 ... 307 |

| Roll diameter max. | mm | 160 |

| Roll drive AC drive max. | rpm | 6000 |

| Grinding spindle drive - power | kW | 50/75/115** |

| Rpm range | rpm | 5000 (8000) |

| Grinding wheel peripheral speed | m/s | 35 |

| - with key-operated switch switchable to | m/s | 50 |

| - with additional flange monitoring switchable up to | m/s | 63 |

| Grinding wheels - diameter | mm | 400 ... 600 |

| Grinding wheels - width | mm | 160 ... 300 |

| Rotary table-Ø | mm | 800 ... 2500 |

| * optionally | m/min | 20 |

| ** max. spindle power is dependent on size | ||

| (Subjet to technical modifications) | ||