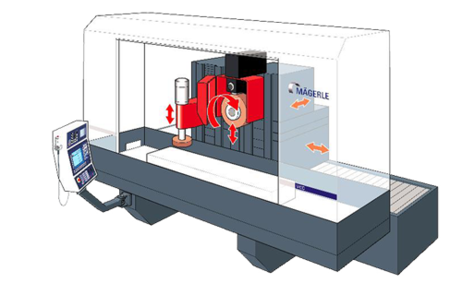

MGC SPECIAL

The standardised Mägerle modular concept can be freely configured to provide individual solutions. Grinding centres which are completely tailored to specific customer requirements are developed within the scope of a proven product range. Single and multiple spindle systems with a horizontal or vertical arrangement can be combined as desired with stationary workpiece carriers, swivelling table or rotary table, in any dimensions.

Tailor-Made Grinding Centers For User-Specific Requirements

The result in all cases is a made-to-measure tool which fulfils the high requirements on manufacturing quality in the automotive, aviation and hydraulic sectors, in turbine construction and mechanical engineering, as well as in the roller bearing and tool industry, with optimal cost effectiveness.

Specifications

| Linear Axes | |

|---|---|

| Max. Travel X | 5,500 mm |

| Max. Travel Speed X | 20,000 mm/min |

| Max. Travel Y | 1,200 mm |

| Max. Travel Speed Y | 30,000 mm/min |

| Max. Travel Z | 900 mm |

| Max. Travel Speed Z | 20,000 mm/min |

| Spindle Drive | |

| Max. Spindle Power | 115 kW |

| Max. Number of Revolutions | 30,000/ min |

| Max. Grinding Wheel Diameter | 1150 mm |

| Max. Grinding Wheel Width | 300 mm |

| Swiveling Axes | |

| Swiveling Range A | 210° |

| Swiveling Range B | 360° |

| Swiveling Range C | 360° |

| Workpiece Data | |

| Rotary Table Diameter | 2,500 mm |